The Role of AI in the Oil and Gas Value Chain - Upstream Segment

With the recent hype surrounding ChatGPT created by OpenAI, I thought I would continue my artificial intelligence (AI) series by exploring a few potential applications of AI in oil and gas operations. Previous blogs in this series examined AI’s role in regulatory compliance and the path to ethical AI, providing the perfect segway into AI’s role in the oil and gas industry.

As AI technologies proliferate, they promise to change everything from how we live to the way companies and corporations operate, create value, and engage with their consumers. The main drivers of this growth are increasing processing and storage power, abundant data availability, and AI algorithmic advancements. While these drivers are well-known, their effects are not, and few if any oil and gas companies are completely AI-ready.

In the oil and gas industry, several AI applications have emerged as companies increasingly supplement advanced data processing and simulation technologies with AI and ML capabilities. At the same time, other industries have also made advances in AI and ML that can be applied to various oil and gas operations.

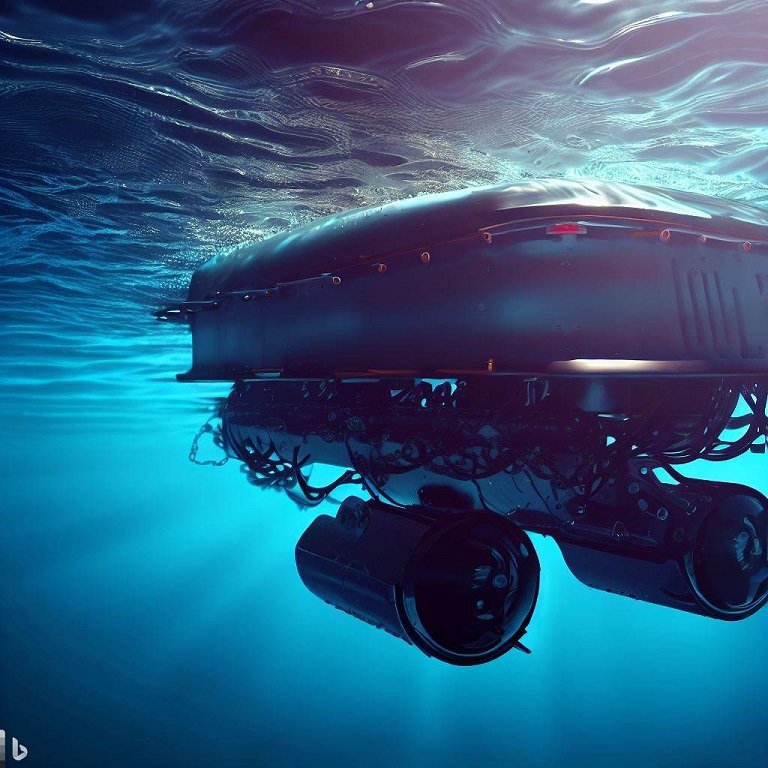

For example, oil and gas companies have started to experiment with autonomous underwater drones that are seeing rapid innovation and adoption, similar to aerial drone systems.

Similarly, AI-enabled vehicles are bringing a wide range of opportunities to offshore oil and gas operations through seabed surveys, met-ocean data gathering, oil spill detection and inspection, and underwater intervention.

In the first part of the series, I will focus on the "upstream" segment of the oil and gas industry where AI is used to optimize field development from exploration to production.

This includes using AI to:

Interpret seismic data to identify hydrocarbon deposits

Identify optimal locations for drilling operations

Optimize recovery

Monitor and investigate with autonomous vehicles for maintenance

Automate installations for production without routine personnel, reducing logistics and safety exposure.

ML algorithms are able to consider several factors important to overall drilling strategies such as equipment ratings, seismic vibrations, strata permeability, and thermal gradients. When layered, the data collected can be used to determine the optimal drilling direction, and how it should be controlled (that is the rate of penetration) as it passes through the ground.

The data collected not only allows upstream operators to monitor the overall performance of the well and make intelligent decisions to improve drilling operations, but is also analysed using a predictive algorithm, to determine if downhole conditions are conducive to potentially catastrophic events such as lost circulation, stuck pipe, or blowouts; and provide recommendations to the control systems to minimize such occurrences.

Advanced imaging technologies play a key role in identifying drilling locations. However, in most cases, details on specific pressure, volume, temperature, and permeability characteristics of the reservoir can only be obtained after a drilling test or by drilling pilot wells. Below is an example of a subsea laser metrology conducted by 3D at Depth using Differential Absorption LiDAR. It took only 2.5 hours to complete in comparison to traditional technology alternatives that are more expensive, provide less visual information, and can take up to 9-12 hours for completion.

Another AI technology that upstream operators are using alongside ML algorithms is Fuzzy logic (an AI-based system) that can be used for prediction and reasoning when information is unreliable and / or incomplete, making it particularly useful to fill in informational gaps during reservoir characterization, enhanced recovery, well stimulation, and infill drilling.

I cannot conclude this initial section without highlighting the essential role played by Engineering, Procurement, and Construction (EPC) in upstream projects. AI technologies can enable EPC firms to make effective and efficient design choices and are capable of revolutionizing project delivery by challenging the traditional sequential project maturation process used by most EPC players.

Stay tuned for Part 2 of this series where I will be discussing the role of AI in the midstream and downstream segments of the Oil and Gas Value Chain.

Until then, learn more about how Citation Manage™ can help simplify your compliance, whether you’re dealing with co-generation facilities or upstream and downstream oil and gas development and refining. The energy and oil and gas sectors encounter a complex set of environmental regulations and mandates, which must be addressed in various locations and regulatory frameworks. Citation Manage™ will manage and track permits and their associated conditions along with simplifying compliance with global environmental regulations/directives in the management of air emissions, water quality metrics, soil contamination and hazardous waste tracking.

Learn more about the platform and its features.